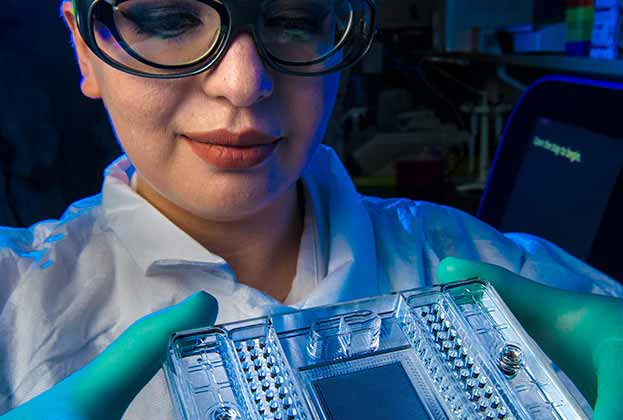

Contract and Development Manufacturing Organisations, or CDMOs, are now playing a pivotal global role in the manufacturing of medicines. This has become increasingly important, especially as we continue to see more UK life science firms looking to deliver their products to market.

What does a CDMO do?

Essentially, it is a third party provider offering life science businesses their knowledge, development and manufacturing capabilities. While traditionally, CDMOs have manufactured more mature products, they are increasingly becoming innovators in development and manufacturing processes, providing more flexibility for those who use their services.

This is being driven by new facility design, technologies and regulatory pathways, which rose to the fore during the pandemic. Pharmaceutical companies turned to CDMO partners to help them develop and validate their manufacturing processes and then deliver at scale. This was essential for faster commercialisation and roll out of the vaccines in the enormous volumes required.

What does the growth in CDMOs mean for the UK life science sector?

The huge advances made in manufacturing technologies, such as new viral vectors that allow for ‘plug and play’ vaccines and gene therapies, coupled with advances in facility design and disposable technology, has created a paradigm shift in the way we approach manufacturing.

Most importantly, CDMOs obviate the need for dedicated single product facilities. While historically the norm, this was restrictive and expensive for many.

How does it work?

The new approach of creating multi-purpose facilities with separately controlled clean rooms means that they can now be used for the development of multiple products, signifying a major regulatory step-change.

What’s more, the use of disposables and flexible equipment means that individual rooms can be used for different products with very fast turnaround times between occupants. One big advantage of this is that if a fast ramp up of product volume is required it is possible to ‘scale out’ by adding additional capacity through the use of multiple rooms at the same scale of manufacture. The traditional approach would have been to move to bigger bioreactors, requiring further regulatory approval taking much longer to approve.

However, this does present new challenges for construction. Built structures need to be designed with scalability and flexibility in mind, allowing for easy expansion and adaptation as product demands increase. This may involve modular construction techniques or the provision of adequate space and utility infrastructure for future growth as part of the initial development.

How easy is it to build a CDMO facility?

The shift towards multi-purpose facilities does require careful design, planning, construction and commissioning. They need to be able to accommodate the diverse needs of different occupiers working on different products and technologies, while at the same time ensuring proper separation and the control of processes. Project teams, therefore, need to build a CDMO facility to be flexible, allowing for easy reconfiguration of spaces to enable technological advances, while limiting wider disruption and downtime.

As these types of facilities are flexible in size and cost, a new model is emerging where they can be embedded in science parks and universities to support emerging life science companies in developing and manufacturing their products for clinical trial in a cost-effective way.

Ultimately, CDMOs require buildings that comply with regulatory standards, facilitate efficient workflow, provide clean room environments, support advanced technologies, offer flexibility and scalability, as well as ensuring safety and security. For these reasons CDMOs remain complex, expensive and ever evolving, but are also key to the growth of the UK life science sector.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)